Warehousing is important for making China's supply chain better. Managing warehouses well helps deliver goods faster and keeps inventory moving. China has strong infrastructure and growing logistics networks. For example, the chain rate in China’s food sector grew from 12% in 2018 to 21% in 2023. This shows how businesses use these improvements to grow. As more brands open 100-500 stores, good warehousing is key to staying ahead in this busy market.

Key Takeaways

Good warehousing in China makes supply chains work better. Use smart tools to track stock and cut costs.

Working with local delivery companies makes rules easier to follow. Their knowledge helps handle China's tricky regulations.

Use digital tools like AI and IoT to work smarter. These tools help track items and fix mistakes in warehouses.

Combine shipments to save money and use space wisely. This plan cuts shipping costs and helps manage stock better.

Check your supply chain often. Small changes can make big improvements in how it works and keeps customers happy.

Overview of China's Warehousing Landscape

China's role in the global supply chain

China is very important in the world’s supply chain. It is the biggest exporter and a center for making and shipping goods. Industries like electronics, clothing, and machines depend on China. Its ports, railways, and highways help move goods easily. This system lets companies ship products quickly to other countries. Using China’s warehouses can help your business save money and meet global needs.

Key warehousing hubs and regions

China has many important warehouse areas. Cities near the coast, like Shanghai, Shenzhen, and Ningbo, are close to ports. These cities handle a lot of global trade. Inland cities like Chengdu and Chongqing are growing as logistics centers. They link western China to the world with roads and trains. If you work in e-commerce, these places are great for fast shipping. Each area has special benefits, so picking the right one helps your supply chain.

Emerging trends in warehouse optimization

Warehouses in China are improving quickly. Companies now use smart systems and machines to store goods better. They also plan warehouse locations and organize storage more efficiently. Changing how jobs are done in warehouses makes work faster. These updates lower costs and help sell products faster. Keeping up with these changes can make your business stronger in China’s busy supply chain market.

Challenges in China's Warehousing Sector

Regulatory and compliance hurdles

Running warehouses in China means following many rules. Laws like the Data Security Law (DSL) control how data is stored and shared. Breaking these rules can lead to big fines, up to 5% of global earnings. Importing and exporting goods also need detailed paperwork. If not handled well, this can slow down your work.

To handle these issues, use compliance software to track rule changes. Partnering with local experts can make customs easier. Following certification rules can lower data storage costs. This helps reduce extra expenses for global companies.

Compliance Area | Challenges | Recommendations |

|---|---|---|

Data Security Law (DSL) | Affects how supply chain data is stored and shared. | Use compliance software to stay updated. |

Customs & Trade Compliance | Needs detailed paperwork for imports and exports. | Work with local experts for smoother processes. |

Data Localization Costs | Increases costs for global companies. | Follow certification rules to save money. |

Geopolitical Tensions | Can delay certification approvals. | Keep track of global relations. |

Penalties for Non-Compliance | Fines can be up to 5% of global revenue. | Plan ahead to avoid breaking rules. |

Geopolitical and trade-related challenges

Global tensions make business in China harder. The US-China trade fight caused tariffs up to 25%. This changed how industries like farming and cars trade. Many US companies now buy from India, Mexico, or Vietnam. They want to depend less on China.

A report says global risks could cost $1 trillion. Over 481 companies in risky areas may be affected. Surveys show 43% of US companies changed their buying plans. Watching global news and spreading out your suppliers can help avoid problems.

Infrastructure and logistical bottlenecks

China’s trade system is strong but has problems. Different rail sizes add 2–3 days to shipping time. This also raises shipping costs by 15% per load. In Central Asia, transport costs are 25% higher than in Europe. These issues make rail less useful than ships.

Old systems and weak technology also slow things down. Global tensions make cross-border work harder. To fix these problems, try new routes and better digital tools. These can make your work faster and cheaper.

Rising labor and operational costs

In recent years, labor costs in China have gone up a lot. Wages are no longer as low as they used to be. Even though workers are more productive, wages are rising faster. This has made China less attractive for cheap manufacturing. Countries like India and Vietnam now have lower wages but similar productivity. Because of this, businesses are rethinking how to manage their costs.

Operational costs have also increased due to higher energy prices. Stricter environmental rules add extra expenses for warehouses. For example, upgrading to energy-saving systems can cost a lot. Meeting emission rules also puts pressure on budgets. These changes affect both your costs and supply chain efficiency.

To handle these problems, you can use automation and technology. Machines can do tasks that need less human work, saving money. Digital tools, like warehouse software, make operations smoother and faster. These solutions help reduce costs and keep you competitive.

Planning is also very important when costs rise. Check your supply chain often to find ways to save money. Working with local logistics experts can also help. They know the market and can offer cost-saving ideas that fit your needs.

Knowing these trends helps you stay ahead in business. By adjusting to these changes, you can solve supply chain problems and succeed in the long run.

Strategies for Warehouse Optimization in China

Using digital tools for better operations

Digital tools are changing how warehouses work in China. These tools make operations smoother and improve supply chain tracking. Systems like warehouse management systems (WMS) help track stock in real time. This reduces mistakes and keeps inventory organized. With these tools, businesses can meet customer needs faster and more accurately.

The growth of digital tools in China is impressive. In 2023, the market size reached USD 57.2 billion. From 2024 to 2030, it is expected to grow by 9.35% each year. Also, 70% of companies in China already use digital strategies. This shows how important these tools have become.

Statistic | Value |

|---|---|

Market Size (2023) | USD 57.2 Billion |

Expected CAGR (2024-2030) | 9.35% |

Percentage of Enterprises Adopting Digital Transformation | 70% |

Using digital tools helps cut costs and improve efficiency. It also makes warehouses run better. In today’s fast-changing market, using these tools is a must to stay competitive.

Combining shipments to save costs

Consolidation warehousing is a smart way to save money in China. It combines shipments from different suppliers into one warehouse. This lowers handling fees and shipping costs. It also uses space better, making inventory easier to manage.

Consolidation has many benefits:

Makes inventory management easier and faster.

Speeds up delivery times for better supply chain efficiency.

Offers flexible options like inbound and outbound consolidation.

Industries like retail, manufacturing, and e-commerce benefit a lot. For example, e-commerce companies can deliver faster while keeping costs low. By using consolidation, businesses can improve their warehouses and compete better in China’s market.

Using AI, IoT, and automation

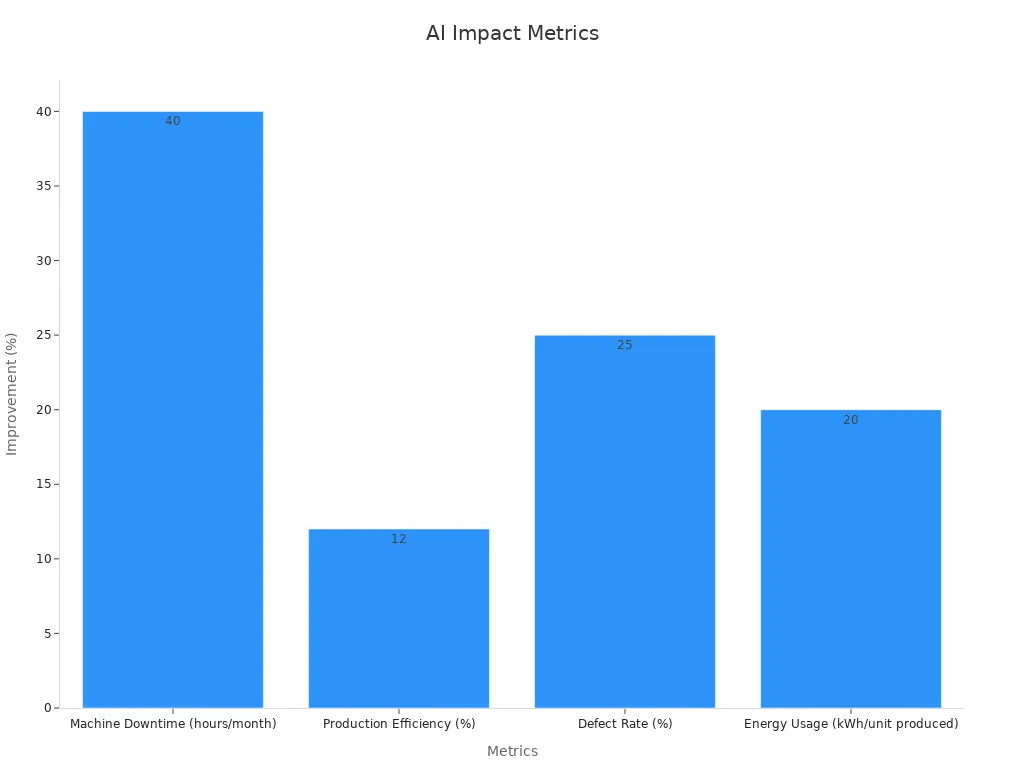

AI, IoT, and automation are making warehouses smarter. These technologies improve processes, reduce mistakes, and give better supply chain tracking. Automated guided vehicles (AGVs) help store items accurately and reduce worker movement. AI systems predict delivery times and match vehicles efficiently. In 2023, these systems handled over 1.5 billion parcels.

These technologies bring big improvements:

Metric | Traditional Manufacturing | AI-Driven Manufacturing | Improvement (%) |

|---|---|---|---|

Machine Downtime (hours/month) | 20 | 12 | 40 |

85 | 95 | 12 | |

Defect Rate (%) | 3.5 | 2.6 | 25 |

Energy Usage (kWh/unit produced) | 150 | 120 | 20 |

Using these tools makes warehouses more efficient. Automation reduces the need for workers. IoT gives real-time data for better decisions. AI improves tracking and smooths operations. Together, these technologies help businesses stay ahead in supply chain management.

Partnering with local logistics providers

Teaming up with local logistics providers in China can improve your supply chain. These providers know the local rules, roads, and market needs well. By working with them, you save time and money instead of building your own resources.

Hiring local providers lowers costs for finding and training workers. They also handle China's tricky labor laws, like social insurance and contracts. This reduces legal risks and lets you focus on your main business tasks.

Third-party logistics (3PL) providers use advanced tools to make work easier. They have systems like warehouse management tools to track goods and improve operations. Their skills in transport, storage, and customs help avoid delays and fines. For example, they can guide you through customs quickly and smoothly.

Local providers are also great at combining shipments. They group goods from different suppliers to cut shipping costs and save space. This method speeds up deliveries and makes your warehouse more efficient. Using their help keeps you competitive in the market.

Tip: Pick logistics providers with good experience in your field. Their knowledge can help solve problems and improve results.

Enhancing inventory management systems

Better inventory management is key to staying ahead in China's fast market. New systems use technology to track stock, predict needs, and organize storage. These tools reduce mistakes and make work faster.

Tracking inventory in real time is very helpful. It shows stock levels instantly, helping you make quick decisions. Cloud-based systems improve teamwork and lower costs, making them a smart choice for all businesses.

AI tools make inventory management even smarter. They study past data to predict orders and use space better. For example, some warehouses in China improved space use by over 60% with these tools. This saves money and supports eco-friendly goals.

Automation is also important for managing inventory. Sensors check storage conditions to keep products safe. These systems save energy and help create a greener supply chain. Adding automation to inventory systems boosts efficiency and gives better results.

Note: Check your inventory processes often to find ways to improve. Small updates can lead to big improvements in efficiency and customer happiness.

Benefits of Optimized Warehousing in China

Saving Money and Cutting Costs

Optimized warehousing in China helps save money. Combining orders from different places increases buying power. This lets you get better deals from suppliers. It also makes ordering easier and builds stronger supplier relationships. These methods lower costs and give better control over spending.

Temporary warehouses are another way to save money. They help store extra items during busy times or sales. You can adjust storage space as needed, which is helpful for short-term needs. This way, you only pay for the space you use and avoid wasting money.

Tip: Use temporary warehouses during busy seasons to handle extra stock without paying for long-term storage.

Better Inventory Tracking and Control

Good inventory management keeps things running smoothly. Optimized warehouses in China use smart systems to track stock live. These systems reduce mistakes and keep inventory updated. This helps prevent having too much or too little stock, keeping customers happy.

Cloud systems make teamwork easier by sharing data quickly. AI tools also help by studying past trends to predict future needs. Some warehouses in China improved space use by 60% with these tools. This saves money and makes storage more efficient.

Note: Check your inventory processes often to find ways to improve. Small changes can save money and make work faster.

Stronger and Safer Supply Chains

Optimized warehouses make supply chains stronger. Better data and practices help you handle risks and recover from problems faster. This keeps your business running even during tough times.

The COVID-19 pandemic showed weak spots in supply chains. Many businesses changed their plans after this. Using advanced warehouse tools helps you plan better and work more efficiently. These updates reduce delays and help you adjust to market changes.

Callout: A strong supply chain doesn’t just recover—it grows stronger and works better after challenges.

Faster delivery and improved customer satisfaction

Quick delivery is very important for keeping customers happy. Today, people expect fast and reliable service. Better warehousing in China helps by making operations smoother and cutting delays. When products arrive quickly, customers are happier and more likely to buy again.

Smart tools like warehouse management systems (WMS), automation, and AI make this happen. These tools help organize stock and speed up orders. For example, automated systems can find and pack items in minutes. This saves time and gets orders ready faster.

Picking the right warehouse locations also helps with quick delivery. Warehouses near ports or railways cut travel time a lot. This means products can reach even faraway places faster. It also helps serve more customers in different areas.

Fast delivery makes customers happy. Happy customers leave good reviews and tell others about your business. This improves your brand and brings in more buyers. Also, satisfied customers return fewer items, saving you money and effort.

Tip: Listen to customer feedback to improve delivery. Small changes, like better packaging or faster routes, can make a big difference.

Focusing on quick delivery builds trust with customers. When they know they can count on you, they will pick your business over others.

Improving warehouses in China helps make supply chains stronger. It lowers costs, boosts efficiency, and speeds up deliveries. Using smart tools and methods keeps you ahead in this busy market.

Key Points:

Solve Problems: Try digital tools to manage rules and high costs. Work with local experts to handle laws and shipping easily.

Use New Tech: Add AI, IoT, and automation to improve work. Combine shipments to save money and use space better.

Helpful Tip: Begin with small steps like upgrading stock systems or trying shipment grouping. Small changes can bring big results over time.

FAQ

What are the key benefits of warehousing in China?

Warehousing in China helps save money and speeds up delivery. Coastal cities like Shanghai and Shenzhen ship goods worldwide quickly. Inland areas like Chengdu connect to western markets efficiently. Better warehouses improve stock management and keep customers happy.

Tip: Pick warehouse locations based on where your customers are.

How can I reduce warehousing costs in China?

Cut costs by using automation, combining shipments, and hiring local logistics experts. These methods lower worker costs, use space better, and simplify tasks. Temporary warehouses during busy times also help save money.

Note: Check your supply chain often to find ways to save.

What technologies improve warehouse efficiency?

Tools like AI, IoT, and warehouse systems make work faster. AI guesses future needs, IoT tracks stock live, and WMS organizes items. Machines like AGVs speed up tasks and reduce mistakes.

Technology | Benefit |

|---|---|

AI | Predicts needs |

IoT | Tracks stock |

WMS | Organizes items |

Why is partnering with local logistics providers important?

Local experts know China's rules, roads, and markets well. They make customs easier, lower legal risks, and save money with shipment grouping. Their knowledge ensures faster and smoother deliveries.

Tip: Choose providers with experience in your business area for better results.

How does optimized warehousing improve customer satisfaction?

Better warehouses mean faster deliveries, accurate stock tracking, and fewer mistakes. Customers get their orders quickly and correctly, leading to good reviews and repeat orders. Smart tools like automation and AI make the process even better.

Emoji Insight: 🚀 Fast delivery = Happy customers!

See Also

9 Benefits of Merging Shipments to Cut Expenses

Effective Strategies to Minimize Shipping Delays in Dropshipping

A Comprehensive Guide to Custom Packaging for Branding in China

Reasons to Consider Hiring a Sourcing Agent in 2025

Essential Advice for Locating Professional Sourcing Services